"The engine" of SD MECCANICA

The activities of the technical office

Management, controls and monitoring of products

The technical office of SD MECCANICA works in collaboration with the customer and manages the customer's orders and monitors the phases of the work of the various departments.

Furthermore, the office takes care of checking the finished products to ensure that they comply with the characteristics of the technical documentation provided by customers in the various orders.

The technical office plays a fundamental role in the organization having the responsibility of elaborating and developing the best solutions for the technical needs of the customers, solutions that also aim at optimizing the working cycles and production processes in the various production departments.

The level of competence and know-how of the technical office are key elements and significantly contribute to the quality of performance and to obtaining excellent products from production.

Efficient management of the technical office helps to keep production costs low and guarantee maximum customer satisfaction.

Competence and professionalism

Updated hardware and software

the company's technical office is well equipped in terms of hardware and software. The equipment and skills guarantee the perfect management of the incoming orders which are processed to prepare the workings of the machines in production.

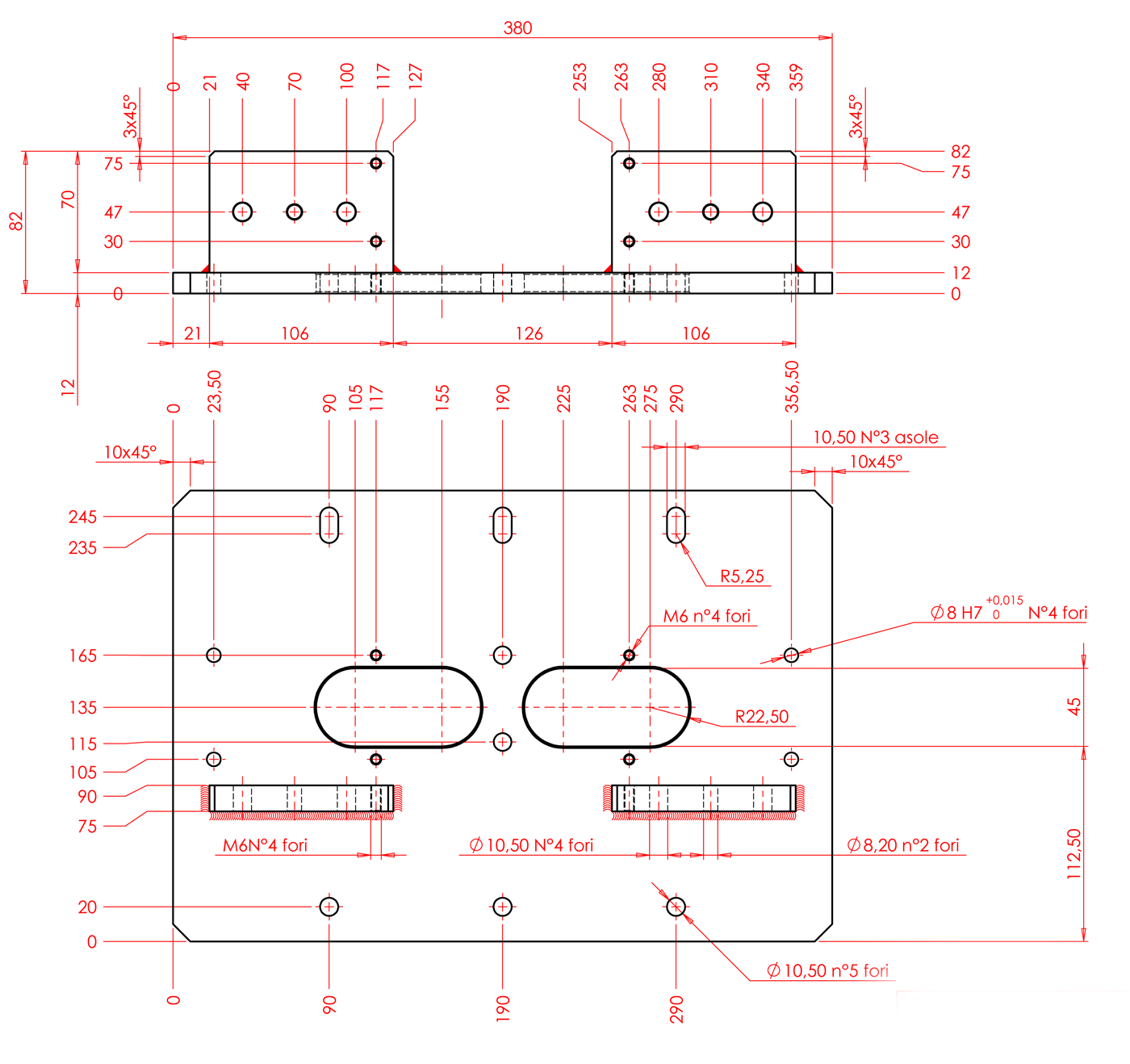

The customer's drawings are carefully evaluated to produce the processing sheets for the department. In addition to the management of orders, the office deals with the planning of orders, to ensure the customer great punctuality and speed of deliveries.

Quality controls with suitable tools

The technical office is committed to verifying the characteristics and quality of the products with the specific instrumentation available.

The quality of SD MECCANICA is the result of targeted interventions in all phases of the production cycle. The company carries out checks on materials before, during and after processing.